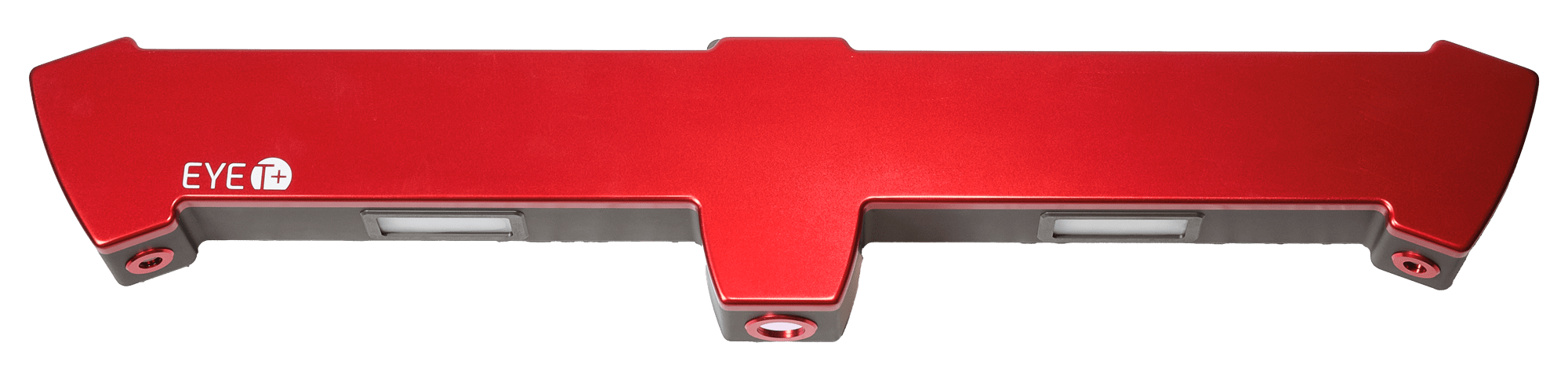

EYET+FLEX

AUTOMATIC DE-PALLETIZING FOR LOGISTICS AND GDO

EyeT+Flex is the 3D vision system for automatically guiding robot manipulators to pick and place boxes, packaging and no-3D objects in general.

The solution is studied to remove the problem of programming de-palletization tasks, everything is completely automated.

EYET+FLEX

EASY PICK AND PLACE FOR LOGISTIC

Eyet+Flex is the 3D vision system for automatically guide robot manipulators to pick and place boxes, envelopes and packages in general.

The solution is studied to remove the problem of programming palletization and depallettization tasks, everything is completely automated.

USE CASES FOR EYET+ VISION SYSTEMS

EyeT+ product family is made a set of intelligent vision systems to achieve robot guidance tasks in many different application cases.

Vision systems, in general, increase the processes flexibility and reduce the mainteinance with respect to mechanical solutions (e.g. mechanical sorters).

BIN-PICKING

The process whereby the robot picks up a certain type of object from a container, belt or pallet in a precise manner (sometimes to the tenth) and loads it into the machine (tool or other).

It avoids the use of noisy, bulky and not flexible mechanical separators or bin tippers.

PICKING FROM MULTIPLE CONTAINERS

This is the process whereby the robot picks up different components from several containers or pallets in a precise manner (sometimes down to the tenth) to go and put together jigs that form an assembly kit or a welding jig or whatever.

It avoids the use of noisy, bulky and not flexible mechanical separators or bin tippers.

→

PICKING OF MIXED OBJECTS

The picking and depositing of different, randomly placed parts from a container or semi-ordered parts from a pallet is a typical process in intralogistics, logistics in the e-commerce world and beyond.

Do you want to find out how machine vision can improve your inbound, outbound and internal goods handling process?

→

MACHINE LOADING

This is the process of automatically loading mainly mechanical components (e.g. die-cast or sheet metal) from containers, pallets or strips into machines for machining, using industrial or collaborative robots.

Precise picking up and depositing of the object is essential, with performance up to a tenth.

→

IN-LINE QUALITY CONTROL

It is the process of checking all production parts for possible cracks or missing components on die-cast or plastic assembled items scenarios. Do your products potentially have problems with cracks (e.g. cracks or scratches) or burrs?

Do you have surface quality issues due to staining? We have the right system for you.

→

EYET+ INSPECT

EASY INSPECTION ON 100% OF PRODUCTION

EyeT+Inspect is the 3D vision system to inspect every single unit coming out from your production line.

The software tools available make the inspection setup task easy to your operator.

USE CASES FOR EYET+ VISION SYSTEMS

EyeT+ product family is made a set of intelligent vision systems to achieve robot guidance tasks in many different application cases.

Vision systems, in general, increase the processes flexibility and reduce the mainteinance with respect to mechanical solutions (e.g. mechanical sorters).

BIN-PICKING

The process whereby the robot picks up a certain type of object from a container, belt or pallet in a precise manner (sometimes to the tenth) and loads it into the machine (tool or other).

It avoids the use of noisy, bulky and not flexible mechanical separators or bin tippers.

PICKING FROM MULTIPLE CONTAINERS

This is the process whereby the robot picks up different components from several containers or pallets in a precise manner (sometimes down to the tenth) to go and put together jigs that form an assembly kit or a welding jig or whatever.

It avoids the use of noisy, bulky and not flexible mechanical separators or bin tippers.

→

PICKING OF MIXED OBJECTS

The picking and depositing of different, randomly placed parts from a container or semi-ordered parts from a pallet is a typical process in intralogistics, logistics in the e-commerce world and beyond.

Do you want to find out how machine vision can improve your inbound, outbound and internal goods handling process?

→

MACHINE LOADING

This is the process of automatically loading mainly mechanical components (e.g. die-cast or sheet metal) from containers, pallets or strips into machines for machining, using industrial or collaborative robots.

Precise picking up and depositing of the object is essential, with performance up to a tenth.

→

IN-LINE QUALITY CONTROL

It is the process of checking all production parts for possible cracks or missing components on die-cast or plastic assembled items scenarios. Do your products potentially have problems with cracks (e.g. cracks or scratches) or burrs?

Do you have surface quality issues due to staining? We have the right system for you.

→

DO YOU WANT TO KNOW

MORE ON OUR 3D SOLUTIONS?