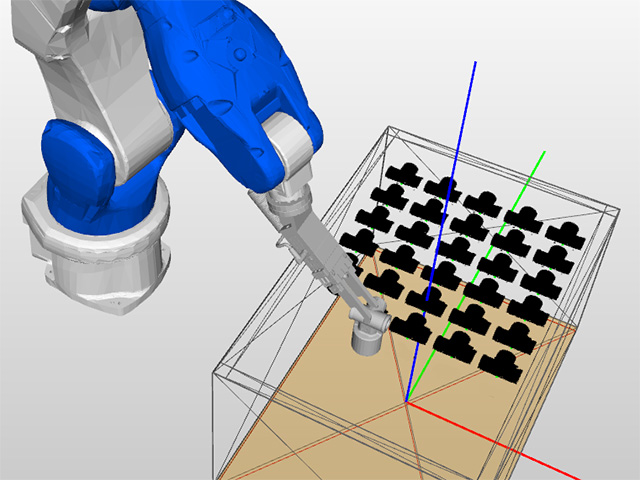

RANDOM BIN-PICKING

FOR INDUSTRIAL AUTOMATION

WHAT IS EYET+ PICK SOLID?

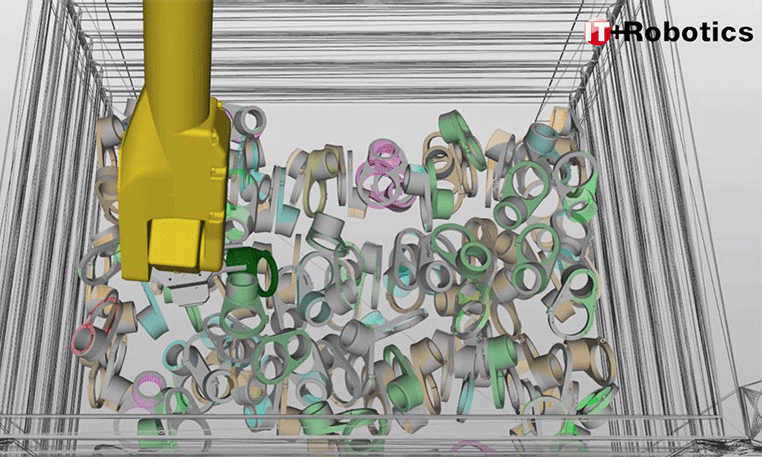

EyeT+ Pick Solid is the random bin-picking system that enables a robotic manipulator to automatically pick objects from a bin, allowing flexible loading of the production line.

BENEFITS OF USING EYET+ PICK SOLID

WHY CHOOSING OUR EYET+ PICK SOLID SYSTEM?

We provide the tools to operate independently:

- Software grown from hundreds of installations worldwide

-

Flexible solution for every bin-picking scenario

- Training course to learn how to use the system autonomously

Accelerate cell deploy and start-up:

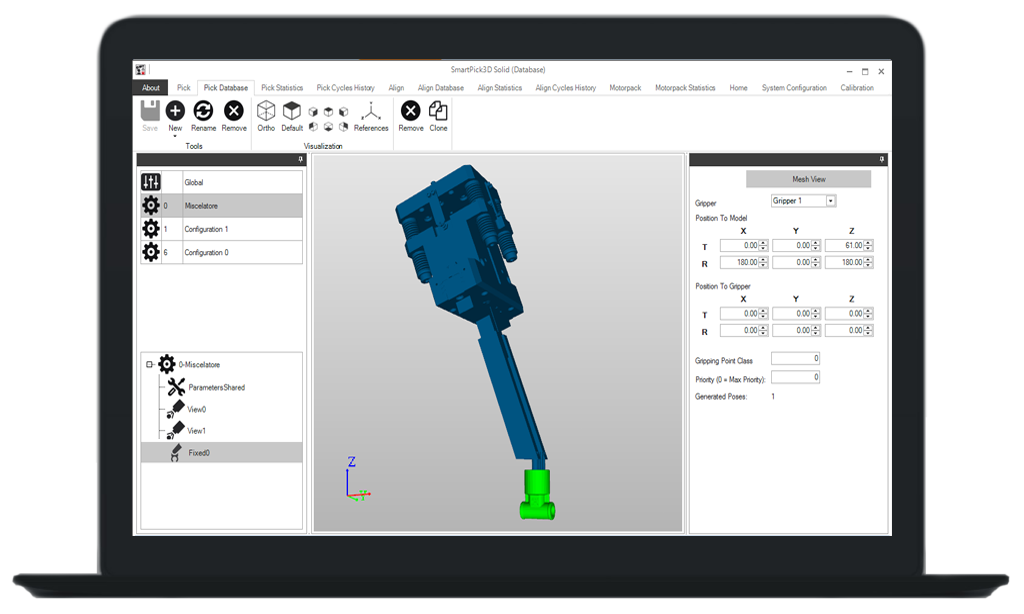

- Reduce gripper design effort with our digital twin for bin-picking

- Configure a new product in just a few steps

- Qualified support available remote or on-site

Improved return on investment:

- Reduced production downtime for new product configuration

- Optimise your process with our digital twin for bin-picking

- Decreased cycle times thanks to predictive algorithms

USE CASES

WHAT MAKES EYET+ PICK SOLID SO SPECIAL?

LOOKING FOR A BIN-PICKING SOLUTION MADE JUST FOR YOU?

Contact us and together we will discuss the 3D robot guidance system that fits your specific requirements!