THE EASIEST WAY TO PROGRAM A ROBOT

WHAT IS ADAPTIVE MANUFACTURING?

Increase the flexibility of your production with our adaptive robot programming solutions.

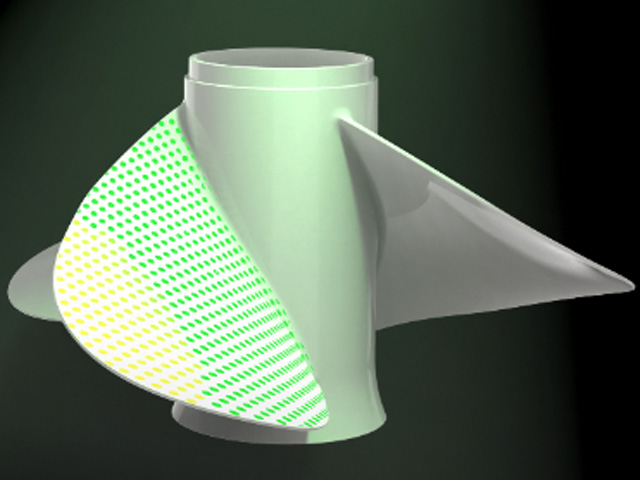

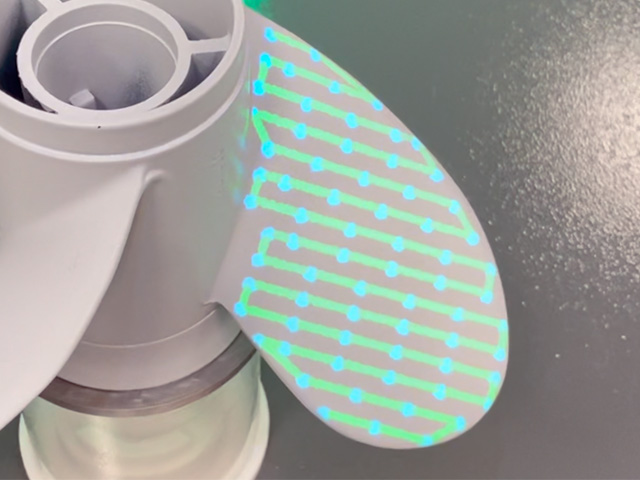

EyeT+ Adapt is the vision system for the automatic generation of machining toolpaths starting from 3D reconstruction of the part, drastically reducing the complexity of robotic programming and ensuring consistent results despite process deviations.

1. RECONSTRUCT

Accurately and quickly reconstruct the position and 3D shape of the workpiece.

2. GENERATE TRAJECTORIES

Automatically generates complex machining paths with maximum control over process parameters (inclination, speed, …).

WHY CHOOSING ADAPTIVE MANUFACTURING?

Adaptive manufacturing, made possible by the integration of 3D vision and advanced automatic path generation algorithms, is the natural evolution to previous approaches to robot programming, as shown in the comparative table below:

Solution

Key Points

Process done manually

Point-to-point robot programming

Collaborative robot programming via manual guidance

Learning through operator tracking systems

General purpose offline robot programming

Adaptive manufacturing with EyeT+ Adapt

WHICH ARE OUR PRODUCTS FOR ADAPTIVE MANUFACTURING?

SUPPORTED ROBOTS

This list is constantly updated.

WOULD YOU LIKE TO RECEIVE MORE INFORMATION

ABOUT OUR ADAPTIVE MANUFACTURING SOLUTIONS?

WOULD YOU LIKE TO RECEIVE MORE INFORMATION