ADAPTIVE ROBOTICS FOR SURFACE FINISHING

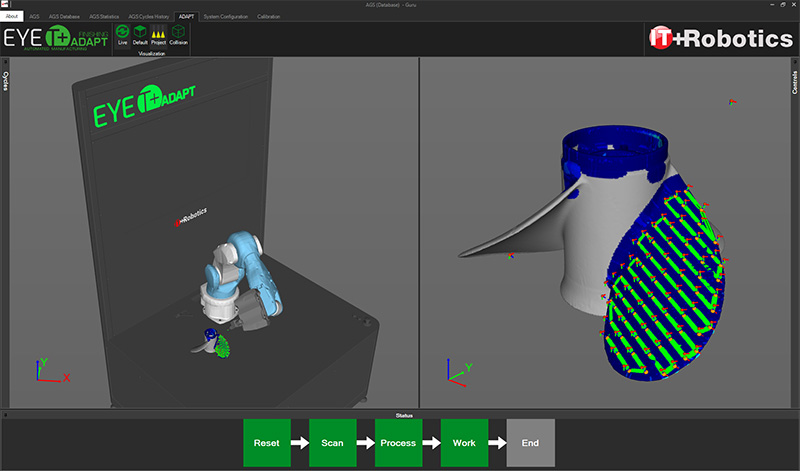

WHAT IS EYET+ ADAPT FINISHING?

EyeT+ Adapt Finishing is the vision system for automatic generation of surface finishing toolpaths, starting from 3D reconstruction of the part, thus drastically reducing the complexity of robotic programming and ensuring consistent results despite process deviations.

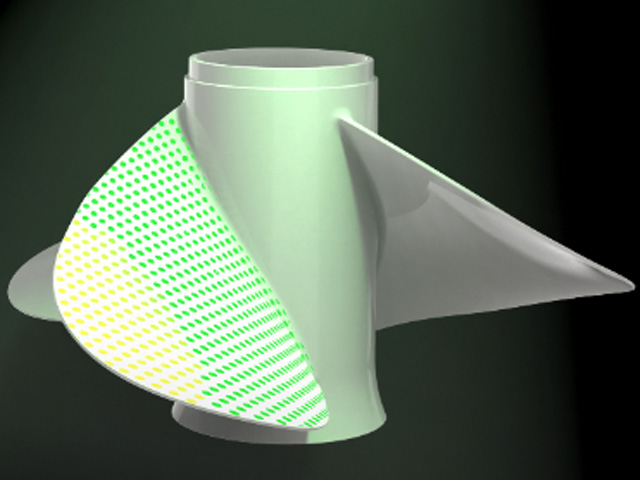

1. RECONSTRUCT

Accurately and rapidly reconstruct the position and 3D shape of the product to be worked.

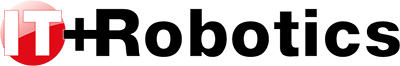

2. GENERATE TOOLPATHS

Automatically generate complex machining paths with full control over process parameters (inclination, speed, …).

3. SURFACE FINISHING

Adapt the toolpath according to the geometry of the object, compensating for process deviations for a consistent result.

THE BENEFITS OF EYET+ ADAPT FINISHING:

WHY CHOOSING OUR EYET+ ADAPT FINISHING?

Extend the limits of robotic cells towards high-variability production:

- Enables the processing of always different objects (high-mix/low-volume)

- No need for dedicated fixtures by automatically adjusting to product position and shape

- Suitable for deformed parts, extending the applicability of robotics for production

Forget the complexity of robot programming:

- Does not require skilled robot programmer to manage the work cell

- Automates the creation of complex toolpaths

- Thanks to 3D vision, no manual on-site adjustments are required

Improves return on investment:

- Reduces production downtime for new product configuration

- Automatically adapts trajectories to actual part geometry, ensuring consistent quality by compensating for process deviations

- Transfers the skills of specialized operators into an automated process

USE CASES

WHAT MAKES EYET+ ADAPT FINISHING UNIQUE?

ARE YOU LOOKING FOR AN ADAPTIVE MANUFACTURING SOLUTION MADE JUST FOR YOU?

Contact us and together we will develop the vision system that fits your specific requirements!