COMPLETENESS INSPECTION ON 100% OF PRODUCTION

WHAT IS EYET+ INSPECT COMPLETE?

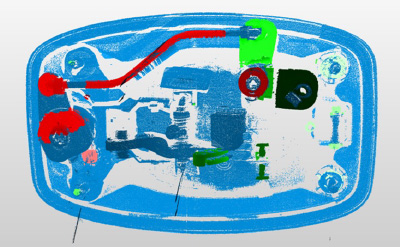

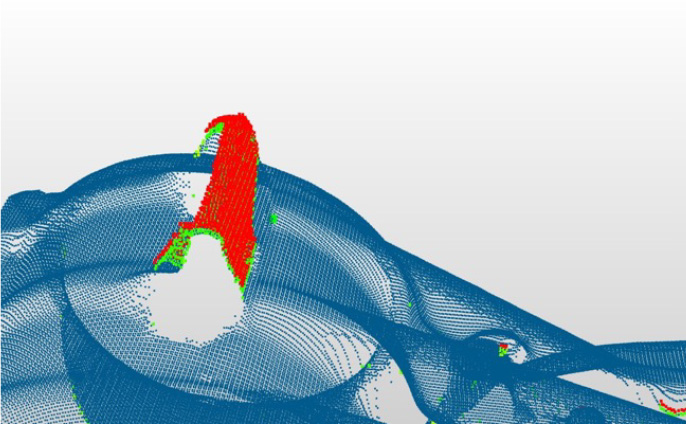

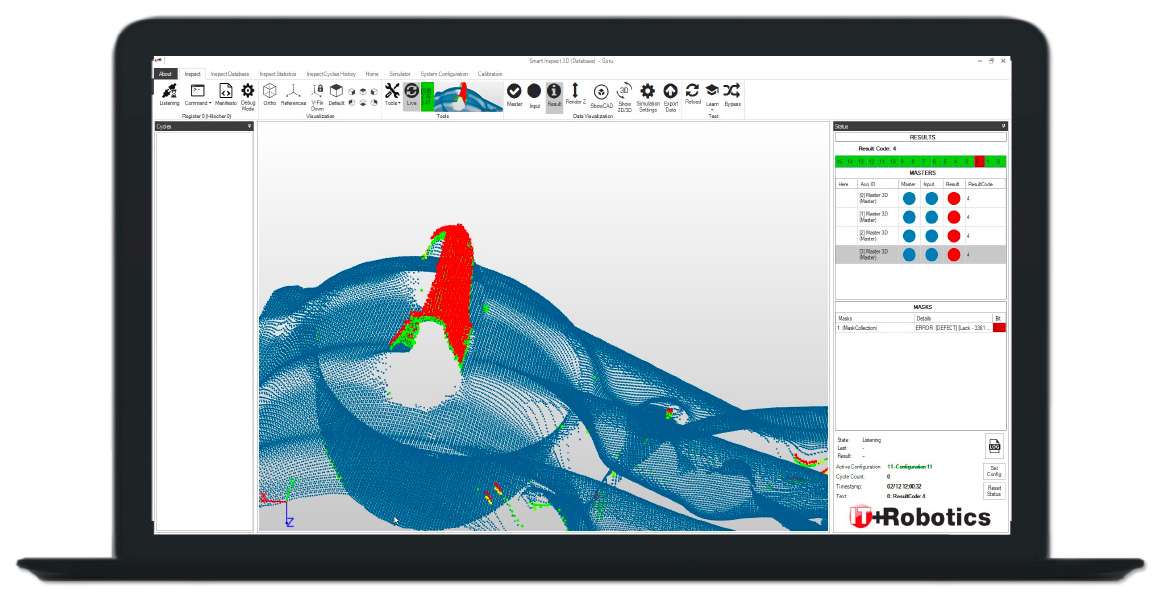

EyeT+ Inspect Complete is the vision system for automatic and objective completeness inspection across 100% of production, detecting defects such as lack, excess or deformation in 3D shape.

1. RECONSTRUCT

Accurately and rapidly reconstruct the 3D shape of the part by combining multiple views.

2. VERIFY

Automatically verify for completeness defects by analyzing the 3D geometry of the product.

3. MONITOR

Optimize and adjust your production by collecting precise and objective inspection results in real time.

THE BENEFITS OF EYET+ INSPECT COMPLETE

WHY CHOOSING OUR EYET+ INSPECT COMPLETE?

Make your quality control objective:

- Ensure the same quality standard on every single piece produced

- Collect real-time data for each product, monitoring the entire production process

- Optimize production by automatic collection of inspection results

Overcome the limitations of 2D analysis:

- Inspection tools are based on 3D geometry, making definition intuitive

- Consistent results on every object, unaffected by lighting conditions or contrast

- 3D vision automatically compensates for differences in product positioning

Improves return on investment:

- Early detection of non-conforming parts avoids unnecessary processing on defective products

- Reduce non-conformities management costs

- Automate quality inspection to objectivize inspection results and increase productivity

USE CASES

WHAT MAKES EYET+ INSPECT COMPLETE UNIQUE?

ARE YOU LOOKING FOR A CUSTOM QUALITY CONTROL SOLUTION?

Contact us and together we will develop the vision system that best suits your specific requirements!