3D MACHINE VISION PRODUCTS FROM

IT+ROBOTICS

WHAT IS AUTOMATED PICKING?

Increase process flexibility with our 3D vision-based robot guidance solutions for automated object picking.

From random bin picking for industrial automation to depalletizing for logistics, EyeT+ Pick solutions handle different scenarios combining maximum reliability and ease of use.

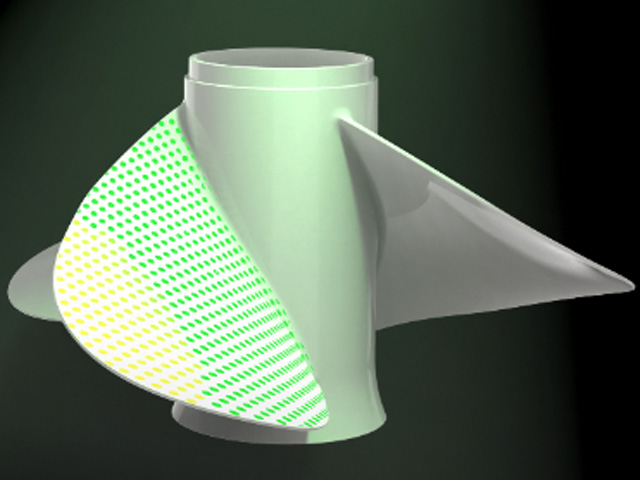

WHAT IS ADAPTIVE MANUFACTURING?

Increase the flexibility of your production with our adaptive robot programming solutions.

EyeT+ Adapt is the vision system for the automatic generation of machining toolpaths starting from 3D reconstruction of the part, drastically reducing the complexity of robotic programming and ensuring consistent results despite process deviations.

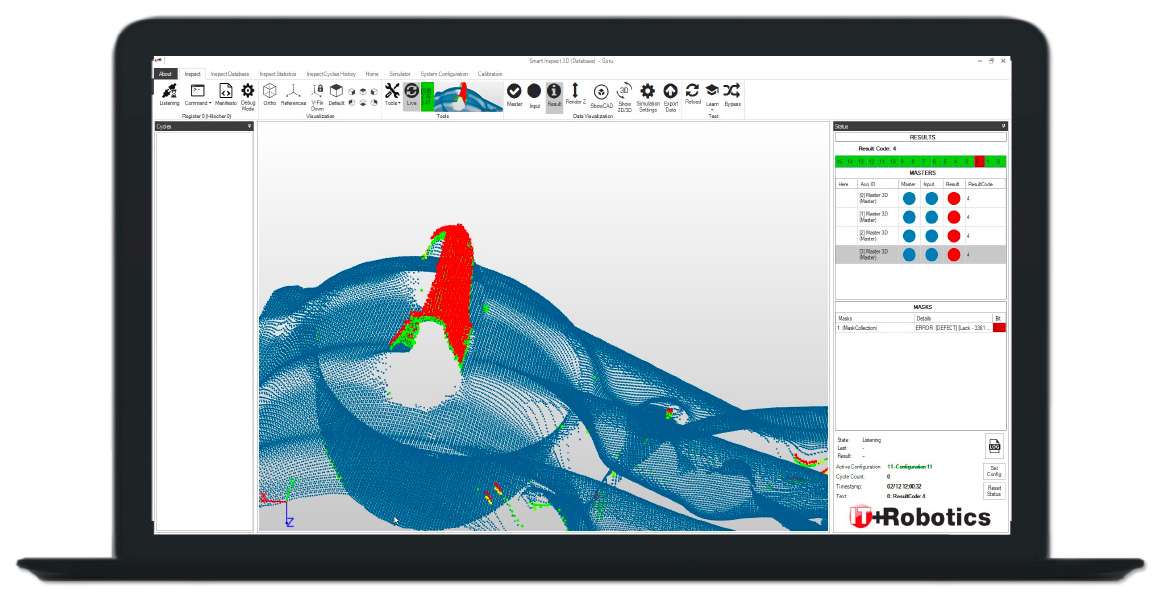

WHAT IS AUTOMATED INSPECTION?

Detect issues in your production and reduce the costs of non-conformities with automatic quality control.

Machine vision techniques allow early detection of defective parts and guarantee the same quality standard on every single product. The data collected in real time allow the production process to be monitored and optimized.

WOULD YOU LIKE TO RECEIVE MORE INFORMATION ABOUT OUR 3D MACHINE VISION SOLUTIONS?

WOULD YOU LIKE TO RECEIVE MORE INFORMATION ABOUT OUR 3D MACHINE VISION SOLUTIONS?