AUTOMATIC DEPALLETIZING FOR LOGISTICS

WHAT IS EYET+ PICK FLEX?

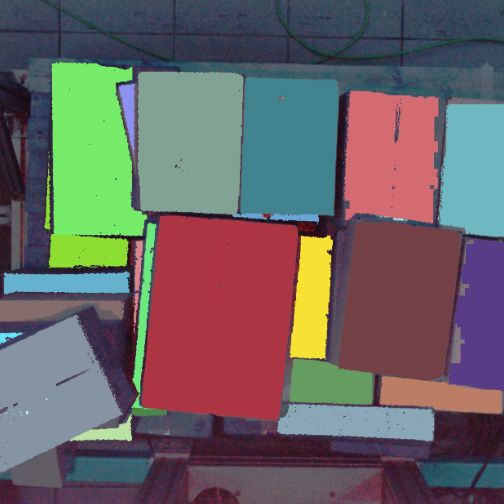

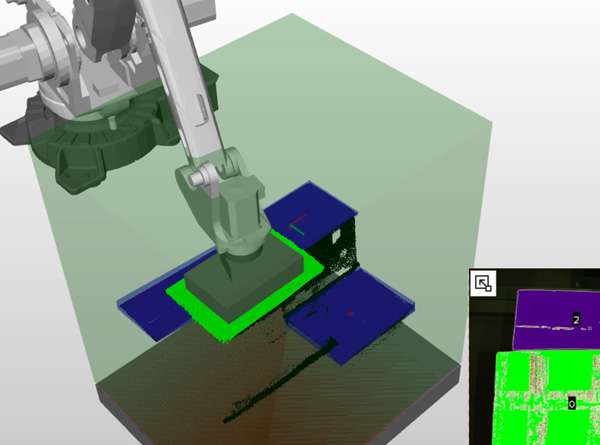

EyeT+ Pick Flex is the vision system for automatic depalletizing, which increases flexibility in logistics flow management, allowing a large number of different products to be handled easily with the same automation.

THE BENEFITS OF EYET+ PICK FLEX

WHY CHOOSING EYET+ PICK FLEX?

Keep up with the latest Artificial Intelligence techniques:

- The system is able to learn classes of objects, localizing items it has never seen before

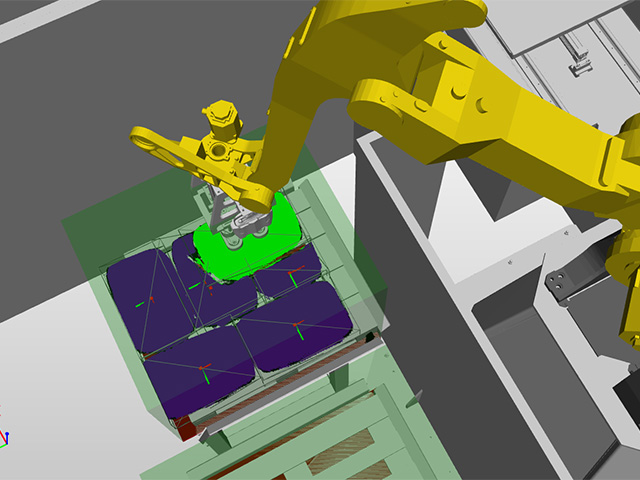

- Automatic calculation of the grasping point based on the class and size of the object

- Automatic calculation of collision-free pick trajectories

Seamlessly manage a large number of SKUs:

- Configurations available for the most common object classes (parcels, envelopes, sacks, …)

- Teach new classes directly on the line in an intuitive way thanks to auto-labelling tools

- Training Centre for centralized and dedicated data management, sharing knowledge between all your plants.

Improves return on investment (ROI):

- Eliminate robot programming costs to define depalletizing schemes.

- Handling of different and ever-changing SKUs, including reflective or transparent objects.

- Continuously improve system performance through continuous learning integrated in the Training Centre.

USE CASES

Food & Beverage logistics

Picking from pallets in food and beverage.

EyeT+ Pick Flex enables picking in food and beverage sector by adapting to a wide range of products, including transparent or reflective materials. The centralized architecture of the Training Centre facilitates the sharing of configurations between plants.

WHAT MAKES EYET+ PICK FLEX SO UNIQUE?

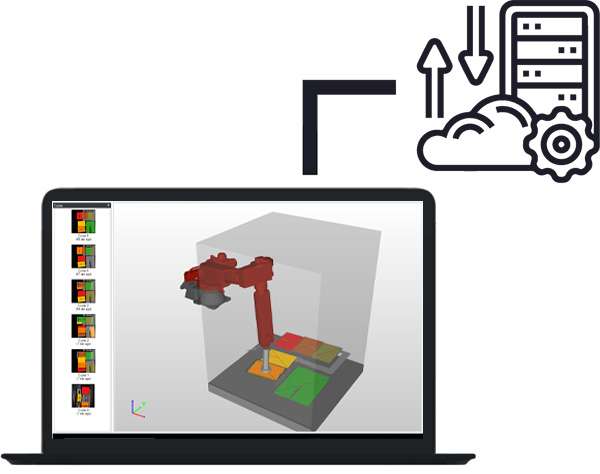

Training Centre

Training Centre is a cloud service for centralized and dedicated data management, sharing knowledge between different plants. It is possible to create new configurations or refine existing ones based on field acquisitions.

ARE YOU LOOKING FOR A DE-PALLETIZING SOLUTION MADE JUST FOR YOU?

Contact us and together we will develop the 3D robot vision and guidance system that fits your specific requirements!