AUTOMATED QUALITY INSPECTION FOR OBJECTIVE RESULTS

WHAT IS AUTOMATIC INSPECTION?

Detect issues in your production and reduce the costs of non-conformities with automatic quality control.

Machine vision techniques allow early detection of defective parts and guarantee the same quality standard on every single product. The data collected in real time allow the production process to be monitored and optimized.

WHY CHOOSING AUTOMATIC INSPECTION?

Automatic inspection overcomes the limitations of manual quality control, offering greater objectivity, repeatability and continuity of operations:

Solution

Key Points

Process done manually

Automatic inspection with EyeT+ Inspect

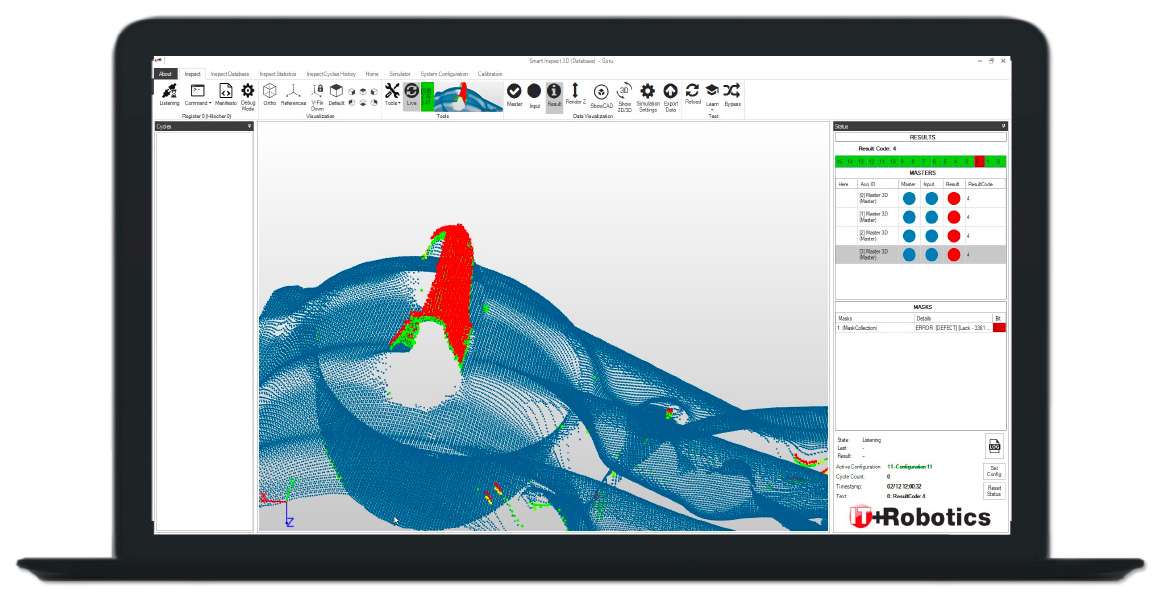

OUR PRODUCT FOR QUALITY INSPECTION

SUPPORTED ROBOT BRANDS

The list is constantly being updated